只有全新的科技才能让我们在夜幕降临的时候

Only the new technology can let us in the night

How to Select a Suitable DC Planetary Gear Motor?

When selecting a suitable DC planetary gear motor, there are several factors to consider. The following advice will help you choose the ideal DC motor for your requirements:

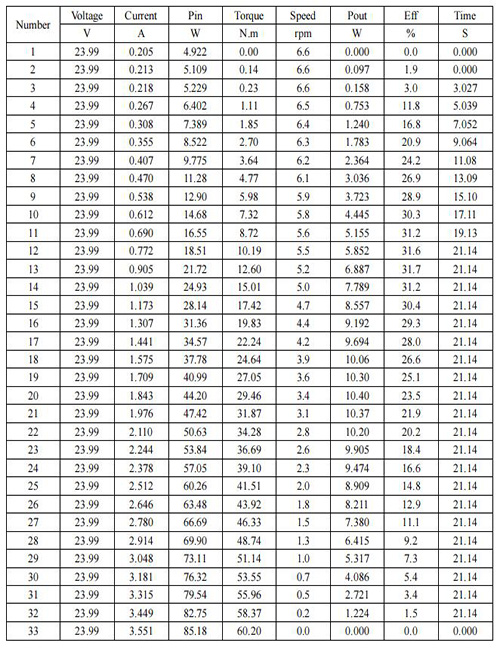

1. Rated Torque: Your application’s need for torque should be considered as you select the best DC planetary gear motor, so keep that in mind when making your selection. For your application, choose a motor with the right amount of torque.

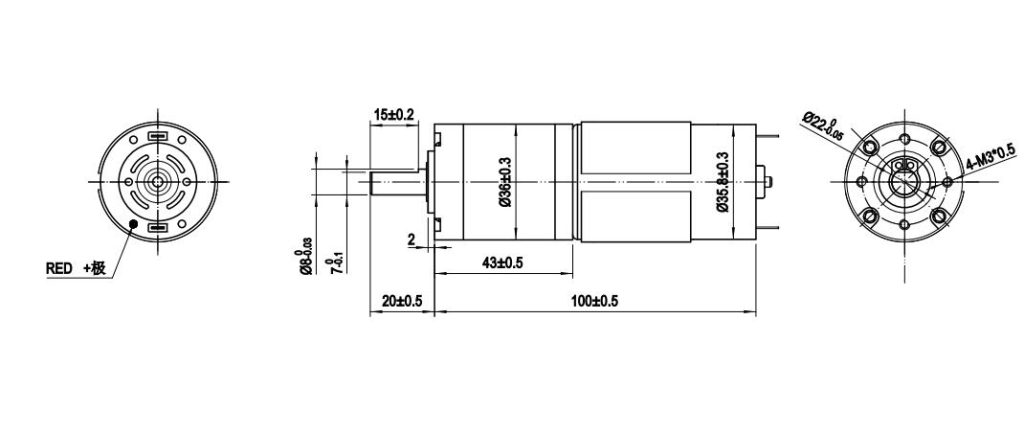

If you need different rated torque, you can choose DC planetary gear motor according their diameter. It includes 16mm planetary gear motor, 22mm planetary gear motor, 24mm planetary gear motor, 28mm planetary gear motor, 36mm planetary gear motor, 42mm planetary gear motor, 52mm planetary gear motor, 56mm planetary gear motor.

2. Rated Voltage : One thing you cannot ignore when picking a DC motor is knowing what DC motor voltage requirement is best for your application. Depending on your application, you might need any of the 6V, 12V, and 24V DC motors.

3. Gear Motor Speed:Calculate the required motor speed. Different speeds, expressed in RPM, are available for DC planetary gear motors. For example: 300rpm dc planetary gear motor. There are many RPM: 10RPM, 20RPM, 50RPM, 55RPM, 100RPM, 150RPM, 200RPM, etc. Pick a motor that can deliver the speed that is ideal for your application.

4. Size requirements:Make sure the motor can fit in your application by taking into account its physical size. Planetary gear motors come in a variety of sizes, including 36mm, 16mm, 22mm, 24mm, 28mm, 32mm, 42mm, 56mm, etc.

5. Efficiency: These motors’ high efficiency is the result of their ability to distribute the load among several gears. Less energy is consequently lost to friction and high temperatures

6. Encoder: A planetary gear motor with encoder is a good option if your application calls for precise control over the motor’s speed and position. Encoders give the control system feedback, enabling precise management of the motor’s position and speed.

7. Is it brushed or brushless?:Considering whether a brushed or brushless motor is better suited for your application will help you decide which is better. Brushless motors are more expensive but have a longer lifespan than brushed motors, which are typically less expensive but need more maintenance.

8. Manufacturer:Pick a planetary gear motor factory that has a solid track record of creating DC planetary gear motors of high quality. Think about things like the warranty, customer service, and the accessibility of replacement parts.

By taking these things into account, you can choose a DC planetary gear motor that will work for your application.